4-point bend test|four point bending test procedure : broker What is the 4 point bend test ASTM? The ASTM D6272 is the standard for the 4-point bend test. This test measures the flexural properties of plastics, including composite materials. Resultado da 8. . 49. 50. ». EroMe is the best place to share your erotic pics and porn videos. Every day, thousands of people use EroMe to enjoy free photos .

{plog:ftitle_list}

webOnlyFans is the social platform revolutionizing creator and fan connections. The site is inclusive of artists and content creators from all genres and allows them to monetize their content while developing authentic relationships with their fanbase. Just a moment. We'll try your destination again in 15 seconds .

The 4-point bend is a popular "scientific" adhesion test. The two forms discussed here share the basics: An elastic substrate, modulus E 2, thickness H sits on two points equidistant from the middle of the sample. A force F is applied from the .Three and four point bend tests are commonly used to determine the flexural strength of a specimen. When a specimen is bent, it experiences a range of stresses across its depth. At .What is the 4 point bend test ASTM? The ASTM D6272 is the standard for the 4-point bend test. This test measures the flexural properties of plastics, including composite materials. Four-point bending tests have been widely used to evaluate the healing efficiency of strain-hardening cementitious materials, which exhibited multiple cracks under continuous .

3-point bending test: It produces its peak stress at the material mid-point and reduced stress elsewhere. 4-point bending test: It produces peak stresses along an extended region of the . The four point bending test described in EN1288-3 (Fig. 1) consists of a 1100 mm by 360 mm glass plate that is held by two support rollers spaced 1000 mm apart. Two bending rollers spaced 200 mm apart press on the glass . This work investigated the mechanical response of engineered cementitious composites (ECC) with high content fly ash by four-point bending tests, and a suitable .Mechanical testing – compression and four-point bending test. Determining the mechanical properties of materials provides important information regarding the structure and the technical application performance.

What is the 4 point bend test ASTM? The ASTM D6272 is the standard for the 4-point bend test. This test measures the flexural properties of plastics, including composite materials. What does a bend test determine? This paper evaluates the fracture properties of concrete using four-point bending test which the beam segment near the midspan crack section is under pure bending. Five different initial crack-depth ratios varying from 0.2 to 0.6 for concrete specimens were explored. The corresponding values of load, crack mouth opening displacement and midspan . 5.2 This test method is recommended for those materials that do not fail within the strain limits imposed by Test Method D790.The major difference between four point and three point bending modes is the location of the maximum bending moment .Bend Testing Equipment Guide; 3 and 4 Point Bend Testing of Semiconductor Devices; Fiber-Reinforced Concrete Testing: Design Changes in ASTM C1609 Equipment; Performing ASTM C1609 on an ADMET eXpert 2655 Universal Testing Machine; How to Perform an ASTM D790 Plastic Flexural 3 Point Bend Test; How to Perform a 3 Point Bend Test on a Universal .

Scope: The Flexural test ASTM D6272 measures the force required to bend a plastic beam under a four point loading system. The test method is used for reinforced or unreinforced materials including high modulus composites and for materials that do not fail within the limits of ASTM D790 (a three point loading test).The most commonly used beam bending test methods include 3-point bending test [100], 4-point bending test [101], disc shape compact tension test [102–104], notched semi-circular bend test [39, 93, 101, 105–107], as shown in Fig. 12, Fig. 13, Fig. 14, and Fig. 15. Among these test methods, the three or four-point bending test is the most .Fig.1(a) shows a guided bend test jig that uses a male and a female former, the commonest form of equipment Fig.1(b) shows a wrap-around guided bend test machine that works on the same principles as a plumber's pipe bender. The strain applied to the specimen depends on the diameter of the former around which the coupon is bent and this is related to the thickness of .

Four-Point Test. A four-point bending test is very similar to a three-point test, But except the load is applied at two points simultaneously, again towards the center of the sample. It’s easiest to calculate the flexural strength when one load or force is applied one-third of the way between the supports and the second is applied two-thirds .

three point vs four bending

Bend tests are usually carried out on a universal testing machine (UTM) using a 3 or 4-point bend fixture. . In the Guided bend test the test specimen is wrapped around a former of a given diameter as per the test specification. The guided bend test is the most common test method used for welding procedure qualification (PQR) and welder .Figure 1 gives the plans for the 4-point bend test apparatus. The dial indicator is below the beam in the test setup as shown in Figure 2. This results in a small upward force due to the spring associated with the dial indicator. The total cost for a setup is given in Table 2. Table 2. Equipment needed for the 4-point bend test. Components .The three-point bending flexural test provides values for the modulus of elasticity in bending, flexural stress , flexural strain and the flexural stress–strain response of the material. This test is performed on a universal testing machine (tensile testing machine or tensile tester) with a three-point or four-point bend fixture. .

While it is easy to imagine why bend testing needs to be performed on rigid materials like plastics (ASTM D790) and concrete (ASTM C1609), in reality bend test applications are common in a variety .Four Point Bending. In this lab, a Four-Point Bend Test is performed on ABS plastic beams from the PASCO Structures System and the Flexural Elastic Modulus for the material is calculated. Grade Level: College. Subject: Engineering. Student .The emphasis in this document is on the methodology of the four-point . bend test. The context . of the test results for service application is the responsibility of the end-user. and is . discussed in . NACE MR0175/ISO (1) 15156. 1-3 _____ Section 2: Principle . 2.1 The four-point bend test is a constant displacement test that is performed by . Analysis of four point bending. The values obtained in this example are dependent on the initial spacing of the applied loads. Also, the shear and moment dia.

The four point bending test described in EN1288-3 (Fig. 1) consists of a 1100 mm by 360 mm glass plate that is held by two support rollers spaced 1000 mm apart. Two bending rollers spaced 200 mm apart press on . four point bending •Can monitor displacement of the loading nose Material forced to fail midspan •Sensitive to geometry and strain rate Four Point Bending •Constant stress between loading noses allows material to fail at weakest point •Useful for materials that do not fail with 3 point bend test Requires larger specimen than for threeMach-1 – 3-point or 4-point Bending Test MA056-SOP11-D v1 BMMT CC#2016-001 BMMT QF4.02.01 v1 CONFIDENTIAL - UNCONTROLLED UNLESS OTHERWISE SIGNED AND/OR STAMPED Page 5 / 9 For the 3-point bending setup: For the 4-point bending setup: Note 1. For the 4-point bending top fin, it is necessary to adjust the distance between the twoA Four-Point Bend Test is performed on plastic beams as shown in Figure 1. As a downward force (F) is applied in the middle of the beam, the flex (Δx) is recorded. The ratio (F/Δx) is the effective stiffness of the length of beam being tested, and is measured directly from the slope of the F vs. Δx graph. The Flexural Elastic Modulus for the material is then calculated.

For the 4-point bending test, the results show the force versus central displacement (note the full load on the bar was 2× force). Similar patterns are noted for both types of flexure tests. All specimens show linear trends, where the response is more linear as the bar size increases. The shape of the load-displacement plot for each specimen .The test can be conducted in different configurations, such as three-point or four-point bending, to simulate different loading conditions. Flexural testing is governed by specific international standards like ASTM D790 and ISO 178, ensuring consistency in procedures and results across different laboratories.Example 4: Cylindrical Four-point Bending A cylindrical specimen is subjected to a four-point bending test. The specimen is 10 centimeters long, and has an inner radius ( ) of 2.5 mm and an outer radius ( ) of 5.0 mm. The specimen is placed on two supports that are 5 cm apart (L), and the actuator applies two forces on the specimen, 3 cm apart.

four point bending test setup

A three point test is easier to perform than a four point test. The deflection measurement in three point tests is commonly measured using the machine’s crosshead position sensor (typically a digital encoder), whereas the four point bend test is commonly measured using a deflectometer.High-frequency, low-force four-point bend tests of small extremity implants allow medical device developers to get products to market faster. Higher frequency testing may deliver a five-fold improvement in time to market, depending on the specimen. . 4-Point Bend Test Demo: An MTS Acumen test system provides fast, accurate test data. Learn . The four-point bend technique provides a reliable and repeatable means of quantifying thin film adhesive properties, and the mixed mode nature of the test approximates stresses and mode mixity conditions often present in thin film structures related to intrinsic growth processes, thermal expansion mismatch, and packaging [8], [9].Importantly, fracture energies .The three standard bending strength tests are the cantilever beam bend test, the three-point bend test, and the four-point bend test. European Standard EN 12384 specifies a bend test to determine the modulus of elasticity in bending. Japanese Industrial Standard JIS 3130 specifies two tests to determine the elastic limit of spring plate or .

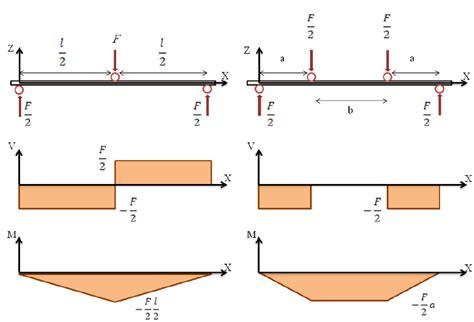

Four-point bending tests, as shown in Photo 1, were performed to allow testing at the center of the sample under constant applied moment and zero shear. Figure 2. demonstrates the four-point bending test load, shear, and moment diagrams. The uniform moment across the center of the pipe sections is: 𝑀𝑀= 𝐹𝐹𝐹𝐹 6 (1) in which:

four point bending test procedure

four point bending test equipment

1.6M views, 26K likes, 2.3K loves, 2.1K comments, 287 shares, Facebook Watch Videos from Telma Santos: Simplesmente não posso deixar de compartilhar este. 1.6M views, .

4-point bend test|four point bending test procedure